StabiliPro™

Excipients for Probiotic Formulations

For Stability, Viability, and Delivery

Excipients are essential to the success of probiotic formulations. These non-active ingredients are designed to protect live microorganisms from environmental stress, extend shelf life, and enable controlled release, making them an important component of high-quality probiotic products.

StabiliPro™ excipients are engineered to support probiotic viability through low water activity environments, synergistic health benefits, and clean-label formulation options.

Supporting Consumers and Manufacturers

As today’s consumers take a more proactive approach to wellness, many are using probiotics preventively to maintain general health and resilience. Despite this growing demand, manufacturers looking to innovate in this space still face significant formulation challenges – from regulatory hurdles and shelf-life stability to the need for further research to expand understanding on the overall benefits of probiotics.

The viability of probiotics is one of the most significant challenges, as these microorganisms are particularly sensitive to harsh processing and high-moisture environments. To address this issue, excipients can play a vital role in maintaining a probiotic’s integrity over its shelf life.

Optimize Products with StabiliPro™

Many manufacturers currently use more probiotics than needed in their formulations to counter the amount that is lost through deterioration during the product development process.

StabiliPro™ excipients help brands gain a competitive edge in the probiotic space. Our proprietary technology preserves the integrity of the probiotic environment and consequentially results in an improved the shelf life.

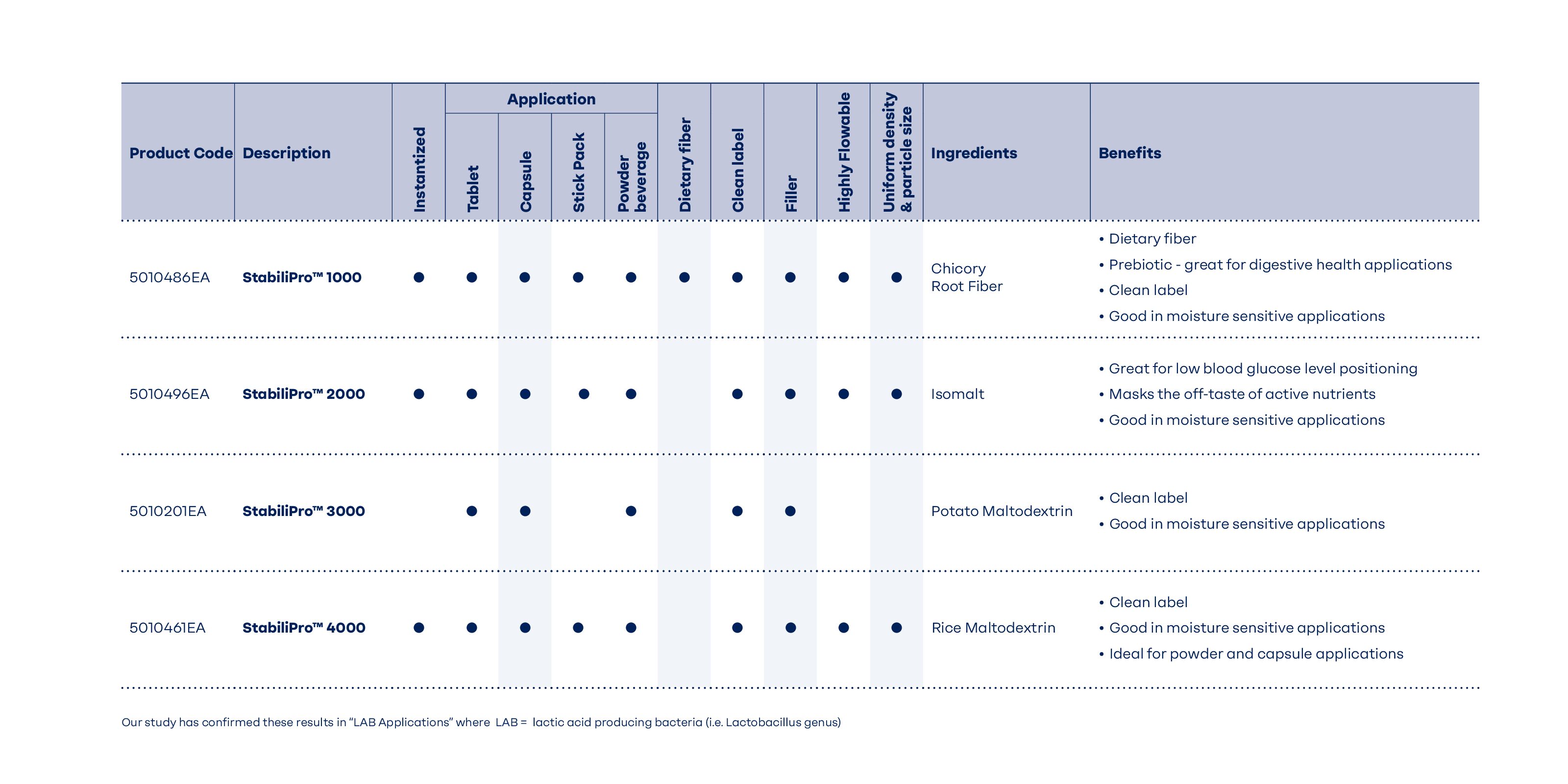

We developed our new clean-label multifunctional excipient portfolio to enhance probiotic stability in a range of formulations, extending shelf life by ensuring maintenance of probiotic stability and reducing the need for probiotic overages.

Key Features of StabiliPro™ Excipients

Instantization is a process that makes the physical characteristics of powdered substances more suitable for various applications.

Agglomeration

The instantization process significantly limits airborne particles by forming larger, heavier granules. This leads to a cleaner production environment and helps prevent material loss and potential contamination.

Learn More

Low Water Activity (LWA)

Probiotics lose viability when exposed to environments with water activity above 0.100aw. LWA formulations help preserve stability by reducing moisture exposure, minimizing the need for excessive dosing of active ingredients, and maintaining probiotic potency throughout shelf life.

Support Wellness Needs

Our formulations can be designed to meet a range of wellness needs. Deliver the full benefits of probiotics for digestive and immune support.

Prebiotic option containing inulin

Low glycemic option containing isomalt

Features clean-label ingredients with simple, transparent declarations

Function and Performance

To ensure the effectiveness and stability of probiotic formulations, various types of excipients are utilized. Each category serves a specific purpose, contributing to the overall quality and functionality of the final product.

Taste Maskers

Improve the taste of the final product

Bulking Agents

Add volume to the formulation

Flow Agents

Support the flowability of powders

Stabilizers

Protect probiotics from moisture and heat to preserve viability over time