NitroShure – Practical Guidance For Feeding Precision Release Nitrogen

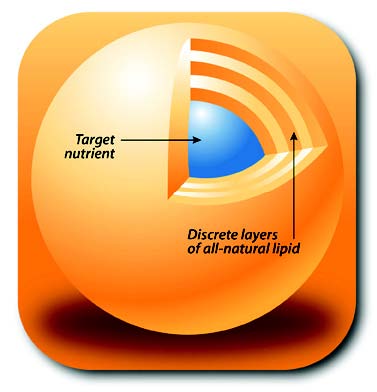

NitroShure™ Precision Release Nitrogen is urea protected by Balchem’s proprietary encapsulation technology (Figure 1). Conceptually it is much like an M&M. Encapsulation controls the rate at which the urea is released in the rumen thus providing a more consistent supply of rumen nitrogen for use by bacteria.

Unprotected urea is almost instantly soluble in the rumen. Because there is significant urease (an enzyme that hydrolyzes urea to ammonia) in the rumen, the addition of urea to diets can lead to rapid spikes in rumen ammonia nitrogen levels. When ammonia levels become too high, too fast, rumen bacteria cannot capture the nitrogen for conversion to high quality microbial protein and it is absorbed into the bloodstream. The liver must then detoxify the ammonia by converting it back to urea which takes energy that could otherwise be used for milk production. Some of the urea may recycle back to the rumen; however, a significant amount of it is excreted in milk as milk urea nitrogen (MUN) or in the urine.

Balancing Energy and Nitrogen

In order for rumen bacteria to grow efficiently, and effectively digest fiber and carbohydrates, they must have a good balance of both energy and nitrogen. In other words, both energy and nitrogen have to be available at similar times to maximize rumen fermentation. When this occurs, bacteria are able to capture nitrogen and synthesize microbial protein. More bacteria means better digestibility of fiber, more energy, and more high quality microbial protein. The end result is better performance by the cow, more milk yield and more milk components.

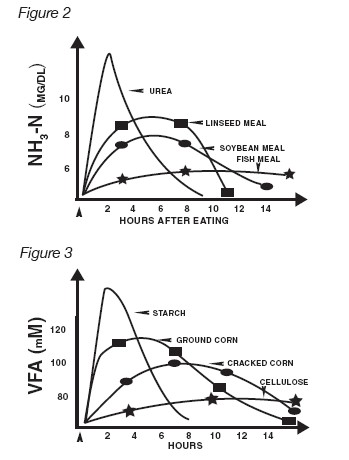

Sources of energy and protein are digested in the rumen at different rates (Figures 2 and 3). Some are fast, some are slow, and some are intermediate. Fast sources of protein can be effectively utilized if there is a corresponding and balanced source of rapidly fermentable energy. Conversely, when nitrogen is released more slowly there needs to be a corresponding source of slower fermenting energy in order to efficiently utilize that nitrogen. When protein and energy are not in balance microbial growth, nutrient digestibility and performance can be adversely affected.

For example, when feeding high levels of unprotected urea, rumen ammonia nitrogen levels will rise very quickly. While bacteria utilizing rapidly fermentable energy sources such as sugars and fast degrading starches can capture some of this nitrogen, much of it will be absorbed from the rumen into the blood. The result is lost energy due to detoxification and lost nitrogen via MUN and excretion in urine. In addition, nitrogen levels rapidly decrease in the rumen, which may lead to inadequate nitrogen levels to maintain optimum bacterial growth later in the fermentation process.

Feeding high levels of vegetable proteins can also result in the energy-nitrogen ratio becoming unbalanced. Diets high in non-structural carbohydrates (e.g., sugars and starches) have resulted in lower rumen nitrogen levels when peptide levels (vegetable proteins supply peptides) become too high (Jones et al., 1998.) Maeng et al., (1976) observed that bacterial growth in vitro increased substantially when amino acids replaced 25% of urea nitrogen but as higher amounts were replaced bacterial growth declined.

Feeding 45 to 90 g of NitroShure Precision Release Nitrogen in diets improves energy-nitrogen balance. A slower release of urea-nitrogen by NitroShure compared to unprotected urea reduces ammonia spikes post-feeding and provides a more consistent supply of ammonia needed for bacterial growth. By providing a more sustained availability of ammonia nitrogen, NitroShure helps ensure that bacteria will have available nitrogen for optimizing bacterial growth even when feeding vegetable protein based diets.

Currently feeding urea?

Feed 45 to 90 g of NitroShure, replacing all but about 10 g of urea (remember fast energy sources such as sugars and fast starches need some readily available nitrogen). If needed to maintain current ration protein level, remove some vegetable protein and back-fill dry matter (DM) space with energy, effective fiber or other nutrients that will improve overall ration quality.

Inadequate Dietary Levels of Soluble Nitrogen?

Feed 45 to 90 g of NitroShure. Reduce vegetable protein or other low quality protein to maintain current ration protein level and back-fill DM space with energy, effective fiber or other nutrients that will improve overall ration quality.

For every 100 grams of soybean meal to be replaced, substitute 20 grams of NitroShure. For every 100 grams of Rapeseed to be replaced, substitute 15 grams of NitroShure.

Vegetable proteins provide peptides and amino acids that have been shown to stimulate microbial protein production. Do not replace all vegetable protein with NitroShure. Maintain 1 to 2 kg of supplemental vegetable protein in the diet.

General Feeding rates:

Maximum rate – 250 g/cow/day

Minimum effective rate – 10 g/cow/day

General Guidelines:

Maintain a minimum of 1 kg/cow/day of soybean/rape seed/canola meal in the diet

- If using CPM ration balancing software, maintain peptide balance at 100% or greater

- Can reduce target peptide balance from 110% to 102%

- If currently feeding urea:

- Continue using urea up to 90 g/cow/day with NitroShure

- Maintain a minimum 10 g/cow/day of urea in the ration

- Add NitroShure to desired level to a maximum of 225 g/cow/day of NitroShure plus urea

- Target Rumen Degradable Protein (RDP) levels

- CPM – 10.0% of DM

- AMTS, NDS, Dalex with CNCPS v6.1 biology – 9.0% of DM

- Total ration soluble protein should be kept between 32 and 38% of total crude protein

- Use high-quality ingredients in combination with NitroShure to back-fill the space created by removing the alternative protein source

- Forage

- High starch concentrates (e.g., high moisture corn, corn meal, barley meal, sorghum and bakery)

- High sugar concentrates (e.g., molasses, bakery/candy and citrus pulp)

- High fermentable fiber concentrates (e.g., citrus, soyhulls and beet pulp)

- Fat